Fe-15Mn-4Si-10Cr-8Ni High Fatigue Resistant Alloy

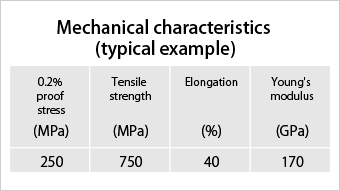

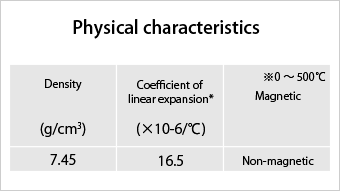

Basic properties and applications of Fe-15Mn-4Si-10Cr-8Ni alloy

We thought that a steel damper with excellent fatigue durability was needed to cope with long-period ground motion, huge earthquakes, and multiple large-scale earthquakes, and developed an FMS alloy* with fatigue durability about 10 times higher than conventional steel materials.(2017 patent registration)

*FMS alloy :Austenitic steel with a composition of Fe-15Mn-4Si-10Cr-8Ni (% by mass) The phase transformation (stress-induced martensitic transformation and its reverse transformation) of the Fe-Mn-Si shape memory alloy is used to improve the durability against repeated deformation. This material was jointly developed by National Institute for Materials Science, Takenaka Corporation and Awaji Materia.

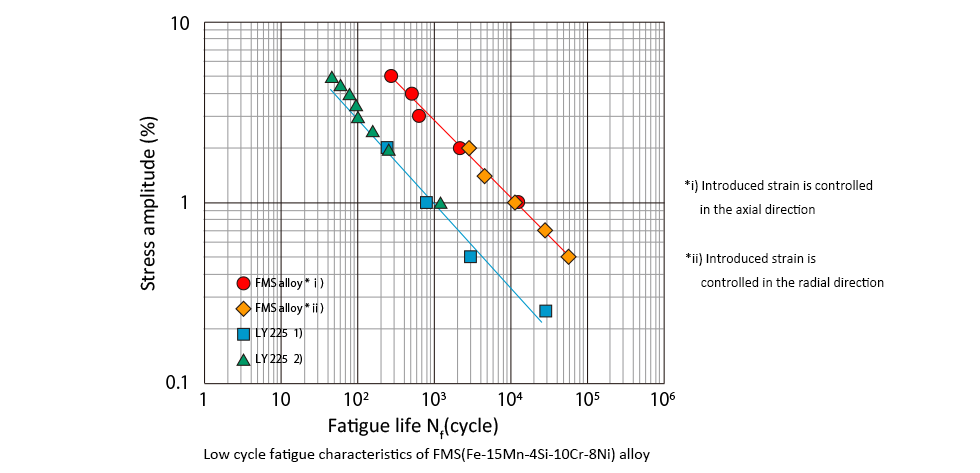

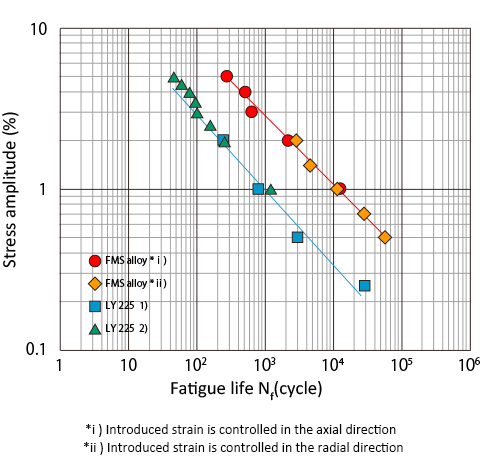

Excellent fatigue durability

・Low cycle fatigue life is about 10 times that of low yield point steel (LY225)

1)I. Nikulin, T. Sawaguchi, A. Kushibe, Y. Inoue, H. Otsuka, K. Tsuzaki, Effect of strain amplitude on the low-cycle fatigue behavior of a new Fe-15Mn-10Cr-8Ni-4Si seismic damping alloy, Int. J. Fatigue 88(2016)132-141.

2)L. Yang, Y. Gao, G. Shi, X. Wang, Y. Bai, Low cycle fatigue property and fracture behavior of low yield point steels, Const. Build. Mater. 165(2018)688-696

Other notable characteristics

・Charpy absorption energy is higher than 250J at -196℃ to 100℃.

Applications

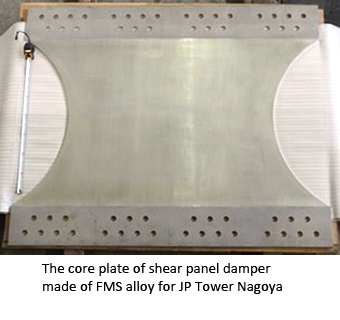

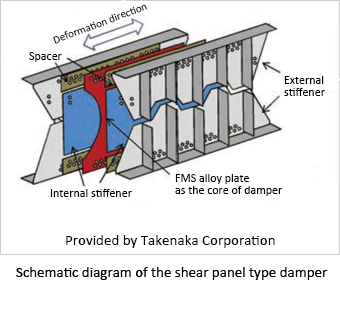

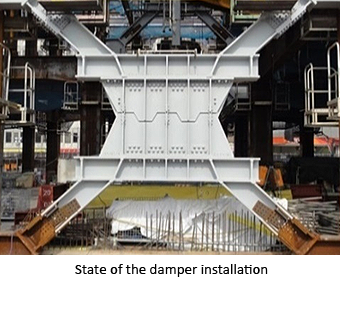

・Shear panel type dampers and brace type dampers those use this alloy as the core material are applied to JP Tower Nagoya and Aichi International Exhibition Center respectively.

Shear panel type damper applied to JP Tower Nagoya

Reference materials

●Press release on May 13, 2014 "Shear panel type damper using FMS alloy has been adopted for JP Tower Nagoya"Developed a seismic damper for buildings using a new alloy with the world's highest fatigue durability(in Japanese)

Discovery of new fatigue relief mechanism and breakthrough in manufacturing technology(in Japanese)

●Received the Architectural Institute of Japan Award (Technology) on April 18, 2016 (reference video in Japanese)

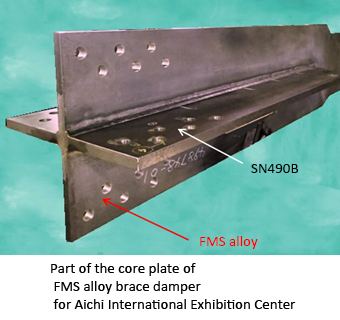

Brace type damper applied to Aichi International Exhibition Center

External link: Developed seismic dampers with approximately 10 times greater fatigue durability(16 pieces applied to Aichi International Exhibition Center)

Reference materials

●Press release on August 30, 2019 "Brace type seismic damper using FMS alloy has been adopted at Aichi International Exhibition Center"

Brace type is now available for seismic dampers, which have about 10 times the fatigue durability of conventional steel materials(in Japanese)

Manufacture of large FMS alloy rolled plates through continuous casting(in Japanese)

●Manufacturing size (Please contact us for sizes other than the following)

・Thickness 8 ~ 34mm, width 1300 ~ 1500mm, length within 10m

List of papers

Papers on FMS alloys and seismic dampers using FMS alloys