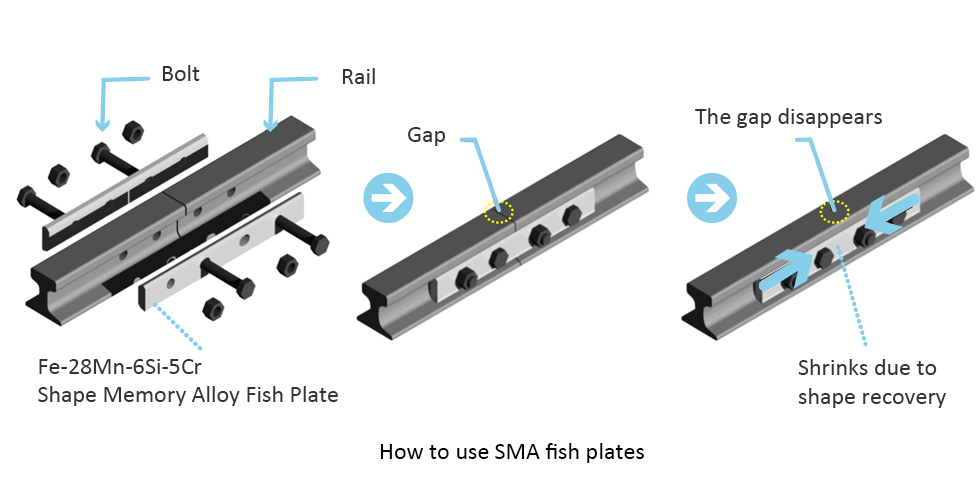

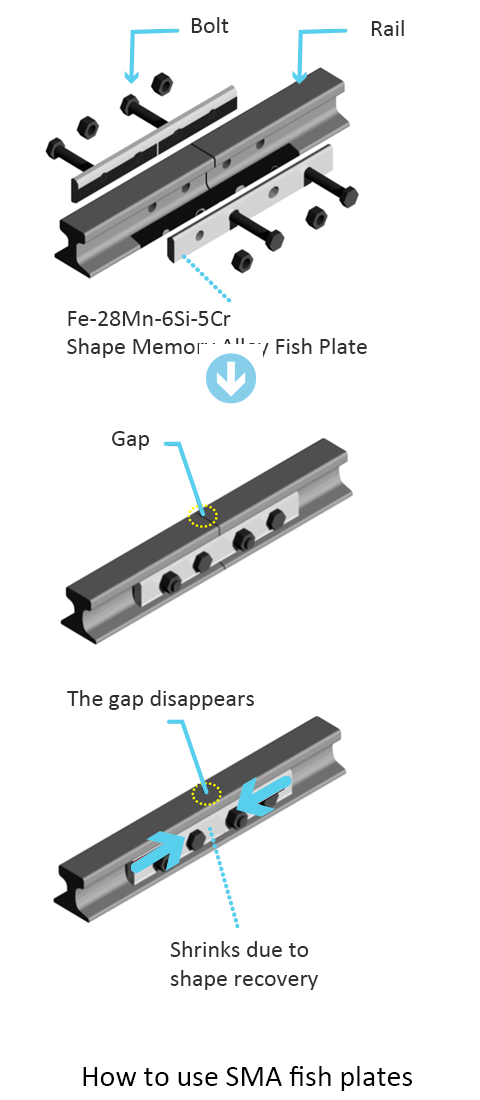

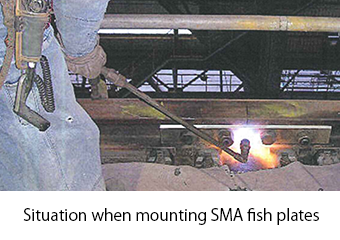

Crane Rail Fish Plates using Fe-28Mn-6Si-5Cr Shape Memory Alloy

Shape Memory Alloy(SMA) Product

We are developing applications for iron-based shape memory alloys invented in Japan.The bolt fastening method is generally used to connect the overhead crane, but since there is a gap between the bolts and the bolt holes, there will also be a gap at the joint between the rails.

This gap becomes a local depression, which causes the vibration of crane wheels and the corners of the rail end faces to repeatedly contact each other, resulting in a larger depression.

As a result, the crane body may fail and the rails may be replaced more frequently.

Welding is a method that does not create gaps, but it takes longer and requires more skill than the bolt fastening method.

Our shape memory alloy seam plate can solve these problems at once.

Realization of gapless rail

Our fish plates realize rail connection without gaps by utilizing the force of shape recovery and maintenance by heating iron-based shape memory alloy.And also achieves the following:

(1)Reduced working time for connecting rails

(2)Reduction of rail replacement frequency

(3)Suppression of crane vibration

(4)Extending the life of overhead cranes and crane runway garters, etc

Greatly contributes to equipment maintenance management

Reference materials

Lifespan Enhancement of Crane Rails, Runway Girders and Overhead Cranes Using Shape-Memory Alloyed Fish-plates

H. TSUJIMOTO, S. KOZAKI, Y. OKUTANI, T. TOYOZAWA, K. ANDO, S. YORIMITSU, N. MATSUISHI, H. ISHII

Nippon Steel Sumikin Technical Report 405(2016)72-80